|

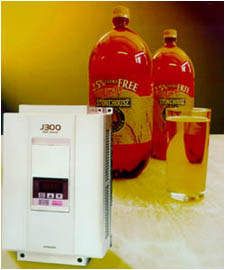

Drives are the

apple of a cider makers eye

Making cider relies on a constant supply of water and at Inch's Cider,

part of the Bulmers group, the maker has its own water supply and

a novel way of maintaining accurate pressure in the system. Inch's

Cider found that mains water pressure varied according to the time

of year and yet needed too maintain a steady 6 bar pressure irrespective

of demand within its system. Nick Forrester, Inch's Cider's engineer,

devised a system whereby the standard PID control features of an

Hitachi J300 inverter could be deployed to control the high delivery

pump. Making cider relies on a constant supply of water and at Inch's Cider,

part of the Bulmers group, the maker has its own water supply and

a novel way of maintaining accurate pressure in the system. Inch's

Cider found that mains water pressure varied according to the time

of year and yet needed too maintain a steady 6 bar pressure irrespective

of demand within its system. Nick Forrester, Inch's Cider's engineer,

devised a system whereby the standard PID control features of an

Hitachi J300 inverter could be deployed to control the high delivery

pump.

Two

stainless steel pumps with 37kW 2-pole motors are fitted within

the system to enable dual redundancy. The pumps, which are switched

periodically to share the duty, are controlled by a fan and pump

rated 30kW Hitachi J300 drive supplied and commissioned by HID.

Pressure sensors located in the pipeline feed a 4-20mA signal directly

to the Hitachi J300 which ramps up the motor as soon as the pressure

starts to fall. To maintain a pressure above the PID control's set

point when demand is low, a simple "donkey" pump is employed - the

pumps do not need to switch in every time a toilet is flushed! Throughout

the commissioning stage, Nick Forrester had a high level of support

from HID's engineering team.

Another Hitachi drive is employed to maintain the pressure from

Inch's two bore holes. These holes - one of which is 200 feet deep,

the other 180 feet - were sited thanks to the help of a water diviner

and supply water for the cider makers' critical cooling system.

The cider must be maintained at a constant temperature for the fermentation

process to be successful. The water is pumped through a heat exchanger

and a line pressure of 2 bar is required. Again, a 30kW Hitachi

J300 is used with PID control.

A further Hitachi inverter is used in the recipe mixing process

to govern the level in a reservoir tank where the cider recipes

are mixed. This complicated application demands that the reservoir

level is maintained even though fill rates vary. Hence, the drive

must control the rate of emptying to keep a constant level in the

tank. The application makes use of PID control but with a useful

feature of the drive's programming to enable the 4-20mA signal to

be scaled. Using the Hitachi inverter's EXS command for the start

point (0 or 1Hz) and the EXE command to set the end point, the 4-20mA

signal can be reversed to expand the band width. The signal is received

from an ultrasonic level probe mounted in the reservoir tank.

The cider process at Inch's Cider, Winkleigh, Devon, site starts

with the apple crushing, before fermenting and then storing the

resultant cider. The cider is then blended to a recipe before the

finished product is transferred by tanker to the bottling plant.

Like any high volume manufacturing process, plant reliability is

critical - another reason the Hitachi drives were selected.

Return

to Case Studies Menu

|